How Do Logistics Moulds Improve Supply Chain Efficiency

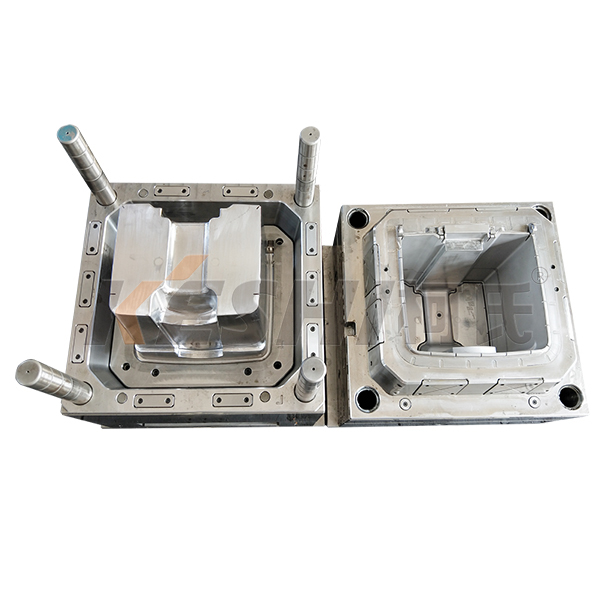

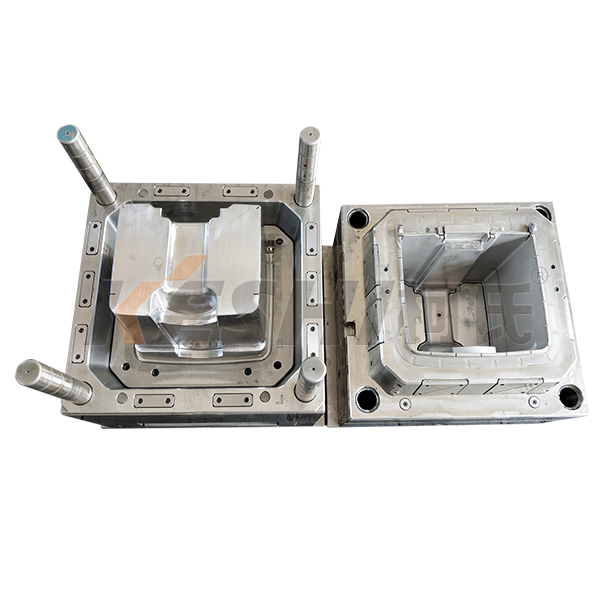

Efficient packaging and storage are critical in modern supply chains, and a Logistics Mould provides consistent, durable solutions for handling products during transport. By producing standardized crates, pallets, or containers, these molds help reduce breakage, simplify stacking, and streamline warehouse operations.

Businesses benefit from consistent product dimensions, which optimize storage space and improve the flow of goods from factory to retailer. A well-designed Logistics Mould supports both domestic and international logistics requirements, ensuring reliable performance under heavy usage.

What Features Should Buyers Consider

When sourcing a Logistics Mould, buyers focus on material compatibility, mold precision, and production efficiency. Durable molds made from steel or aluminum ensure long-term use and maintain consistent product quality.

Other important features include mold size, cavity design, and cooling channels. Multi-cavity molds increase production output, while precise engineering ensures uniformity for stacking and storage applications.

How Does Material Selection Affect Performance

Material choice directly impacts mold longevity and product quality. A Logistics Mould made from reinforced steel or aluminum resists wear, deformation, and corrosion during repeated injection cycles.

For the end product, selecting suitable plastics like polypropylene (PP) or high-density polyethylene (HDPE) ensures containers are strong, lightweight, and capable of withstanding heavy loads and environmental stress during transportation.

Could Customization Enhance Logistics Solutions

Custom molds allow businesses to meet specific packaging requirements. A Logistics Mould can be designed for stackable crates, foldable containers, or specialized pallets to optimize transport and storage efficiency.

Manufacturers offering custom mold solutions help buyers reduce shipping costs, protect fragile items, and improve warehouse organization, providing a competitive edge in logistics operations.

How Does Maintenance Affect Mold Longevity

Regular maintenance ensures a Logistics Mould continues producing high-quality products over long-term operations. Cleaning, inspection, and polishing prevent defects such as warping or uneven surfaces.

Suppliers providing maintenance guidance and support services increase buyer confidence, helping warehouses maintain consistent inventory quality without production interruptions.

Are Efficiency and Production Speed Important

Optimized Logistics Mould designs improve material flow, reduce cycle times, and minimize waste. Features like proper venting, gate placement, and cooling systems allow smooth injection, resulting in uniform containers and pallets.

Higher efficiency translates to cost savings for manufacturers and distributors, enabling faster production of large-volume logistics items.

How Does Market Demand Influence Mold Selection

The logistics and e-commerce sectors drive demand for specialized plastic containers, crates, and pallets. A versatile Logistics Mould allows manufacturers to adapt quickly to market needs, producing products that meet warehouse, transport, and retail requirements.

Flexible mold designs also enable seasonal adjustments, promotional packaging, or adaptations for new product lines.

Could Safety and Compliance Be Critical

Logistics products often carry heavy loads and must meet industry standards. A Logistics Mould that produces containers compliant with ISO, FDA, or other regulatory requirements ensures safe handling and reliability during transport.

Material selection, design accuracy, and quality control all play a role in producing safe, high-performing logistics products.

Are Multi-Cavity Molds Valuable for Large-Scale Production

Multi-cavity Logistics Moulds allow multiple containers or pallets to be produced in a single cycle, increasing output without additional labor or time. This is particularly useful for bulk orders, warehouse operations, and exporters managing large-volume shipments.

Efficiency gains also reduce manufacturing costs while maintaining uniformity and precision in every product.

What Should Buyers Verify Before Ordering

Buyers should assess mold durability, material compatibility, design flexibility, and supplier support when choosing a Logistics Mould. Confirming production capacity, technical specifications, and warranty options ensures reliable and consistent output for logistics and warehousing needs.

Partnering with a dependable supplier guarantees that molded containers, crates, and pallets meet operational requirements, improve handling efficiency, and support smooth, cost-effective supply chain operations.

English

English русский

русский عربى

عربى 中文简体

中文简体