Years of

Experience

Naturally Stands Out

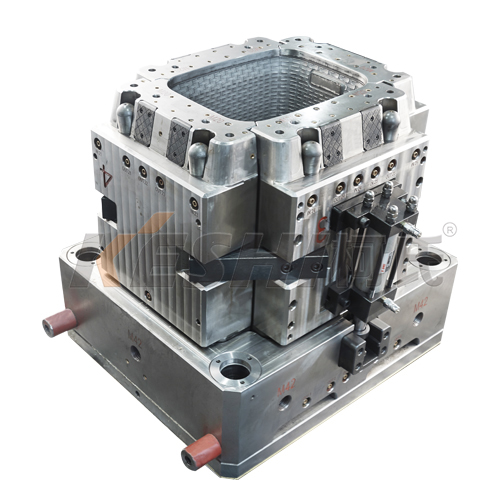

manufacturer & supplier of an extensive range of plastic moulds, Household Plastic Mould, Package Mould, Furniture Mould, Logistics Mould and Pipe Fitting Mould

, etc.We have complete mould-building facilities furnished with the modelling software: UG, CAD/CAM, PROE, SOLIDWORKS, and advanced processing equipment to ensure high-quality mould. We aim to meet and exceed our customers’ expectations through design, competitive prices, fast delivery, and after-sales service.

-

0

Founded in 2018

-

-

0

100 Employees

Diversified Products

-

Mould Technology

Mould TechnologyWhether you have completed a CAD drawing or just an idea or concept, KESHI MOULD could start working together with you on your project. ...

-

Mould Quality

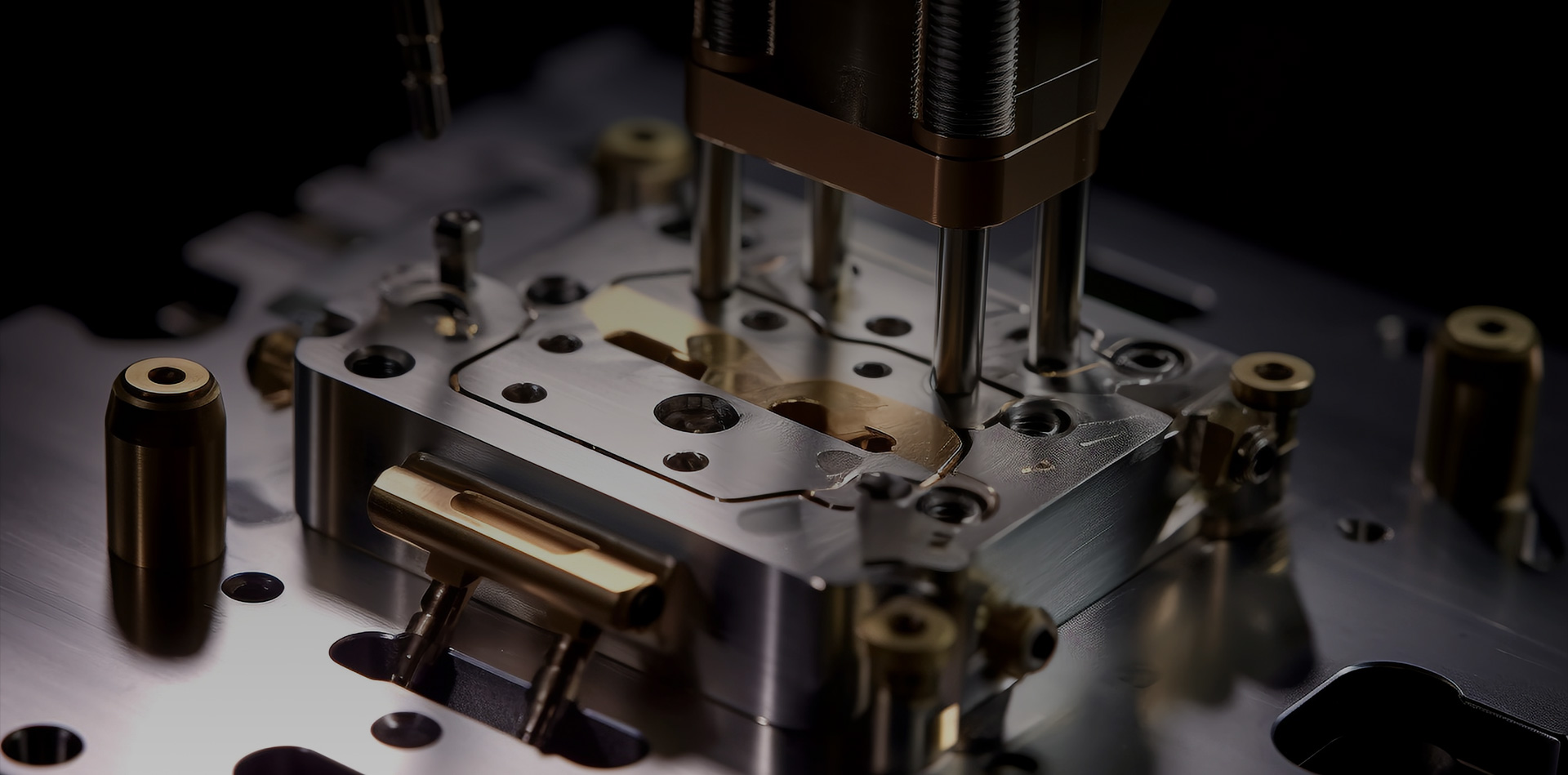

Mould QualityThe latest equipment for quality and productivity provides our skilled craftsmen the accuracy and productivity to efficiently deliver on our quality...

-

Equipment

EquipmentOur machine workshop is operated from a DNC/PC link or network directly from designers to the shop floor, where highly skilled operators create ...

-

Service

ServiceQuick response and exclusive contact, rich experience, reasonable arrangements for processing procedures, follow-up production schedule...

Provide complete solutions, competitive price, and on-time delivery.

News and Information

-

The Hidden Art Behind Every Plastic Objectread More

What Actually Happens Inside a Mold Look around any room and count plastic items. Phones, remotes, w...

-

Innovative Solutions With Plastic Package Moldread More

How Do Plastic Package Molds Improve Manufacturing A Plastic Package Mold is essential for producing...

-

High Precision Solutions With Pipe Fitting Moldread More

How Do Pipe Fitting Molds Enhance Manufacturing Efficiency A Pipe Fitting Mold is a key tool in prod...

English

English русский

русский عربى

عربى 中文简体

中文简体

View More

View More