How Do Household Plastic Molds Improve Manufacturing Efficiency

A Household Plastic Mold plays a vital role in producing consistent, high-quality household products. From storage containers and bins to kitchen tools and organizers, these molds ensure uniformity in size, shape, and finish. Using precise molds reduces production errors and material waste, allowing manufacturers to maintain high output rates without compromising quality.

Efficient molds also shorten cycle times, enabling factories to meet growing demand quickly. For businesses scaling production, reliable molding solutions are essential to sustain operations and reduce downtime.

What Features Should Buyers Consider

When sourcing a Household Plastic Mold, buyers typically evaluate mold material, compatibility with different plastics, and durability. High-quality molds work seamlessly with materials such as polypropylene (PP), polyethylene (PE), or ABS, ensuring end products are strong, heat-resistant, and safe for household use.

Other factors include mold complexity, surface finish, and cavity design. Multi-cavity molds allow manufacturers to produce multiple items per cycle, increasing productivity and reducing overall costs.

How Does Material Quality Affect Performance

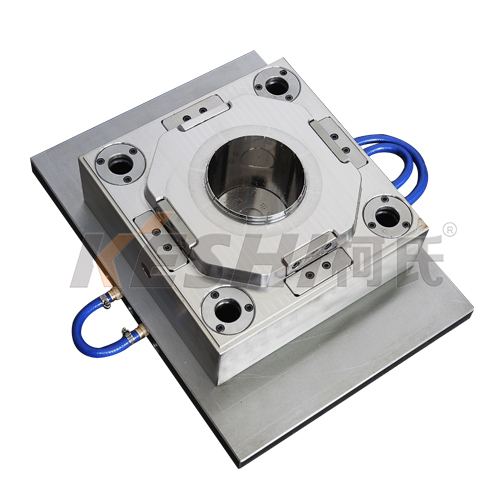

The choice of mold material directly impacts precision and longevity. A Household Plastic Mold made from high-strength steel or aluminum can withstand repeated production cycles without deformation. Superior material quality prevents defects such as warping, flashing, or uneven surfaces.

Additionally, durable molds maintain smooth surfaces for consistent product finish, which is essential for household goods that need a clean and polished appearance.

Are Design and Customization Important

Customization is increasingly important in today’s market. A Household Plastic Mold can be tailored to produce unique product shapes, ergonomic designs, or branded features like embossed logos or textured surfaces.

Suppliers offering custom mold solutions help manufacturers differentiate their products in competitive markets. From stackable containers to kitchen organizers with snap-on lids, unique molds provide added value for distributors and end consumers.

Could Efficient Mold Design Reduce Production Costs

Optimized Household Plastic Mold designs improve material flow, reduce cycle times, and minimize waste. Proper venting, cooling channels, and gate placement ensure smooth injection of molten plastic, improving the consistency of each item produced.

By reducing errors and enhancing production speed, efficient molds lower operational costs, making household products more competitively priced without sacrificing quality.

How Does Market Demand Influence Mold Selection

Trends in home organization, eco-friendly storage, and compact kitchen solutions drive demand for new molded products. A versatile Household Plastic Mold allows manufacturers to adapt quickly to market needs, producing containers, bins, and organizers that appeal to modern consumers.

Flexible mold designs also support seasonal items, promotional products, or limited-edition household goods, helping manufacturers capture niche market opportunities.

Are Safety and Compliance Considerations Essential

Molded household products must comply with safety standards, particularly for food-contact items or children’s products. A Household Plastic Mold that produces items meeting FDA, EU, or other international regulations ensures consumer safety and buyer confidence.

Material choice, surface smoothness, and accurate mold design all contribute to safe, high-quality products suitable for everyday use.

How Does Maintenance Impact Longevity

Regular maintenance extends the life of a Household Plastic Mold. Cleaning, inspection, and occasional polishing prevent defects and maintain production consistency.

Suppliers providing maintenance guidance or support services enable manufacturers to minimize downtime, maintain consistent output, and protect their investment over the long term.

Could Multi-Cavity Molds Enhance Productivity

Multi-cavity molds allow multiple items to be produced simultaneously, increasing output without additional production time. A Household Plastic Mold designed for multiple cavities optimizes factory efficiency and supports large-volume orders for wholesale distributors.

This approach also reduces labor costs and simplifies quality control, ensuring each item meets the same standards of precision and finish.

What Should Buyers Verify Before Selecting a Supplier

Before choosing a Household Plastic Mold supplier, buyers should assess mold durability, precision, material compatibility, customization options, and after-sales support. Requesting sample molds, technical specifications, and warranty information helps ensure reliable production.

English

English русский

русский عربى

عربى 中文简体

中文简体