How Do Pipe Fitting Molds Enhance Manufacturing Efficiency

A Pipe Fitting Mold is a key tool in producing high-quality pipe connectors for plumbing, irrigation, and industrial systems. By ensuring consistent shapes, dimensions, and smooth surfaces, these molds allow manufacturers to produce fittings that assemble accurately without leaks or misalignment.

Using precise molds reduces material waste, minimizes production errors, and shortens cycle times. Manufacturers benefit from higher efficiency, especially when fulfilling bulk orders for commercial or residential projects. A well-designed Pipe Fitting Mold also improves product reliability, which is crucial in industries that require leak-proof and durable piping systems.

What Features Should Buyers Evaluate

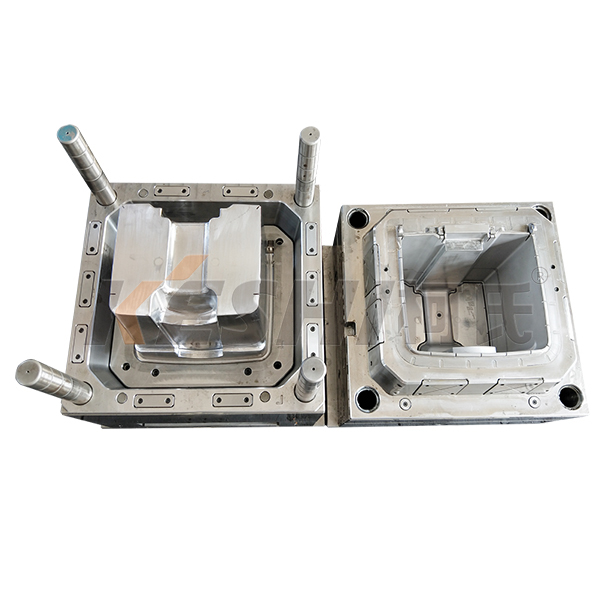

Buyers looking for a Pipe Fitting Mold often consider material quality, mold precision, and compatibility with different plastics or metals. Durable molds made from steel or aluminum resist wear and deformation during repeated production cycles.

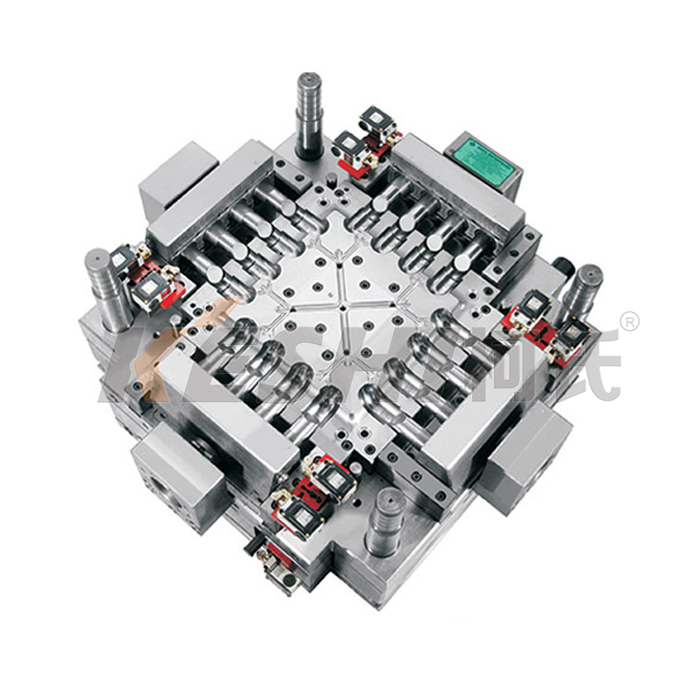

Other considerations include cavity count, venting, and cooling channels. Multi-cavity molds can produce multiple fittings per cycle, increasing output and reducing production costs. The mold design must also accommodate variations in diameter, wall thickness, and connection types to meet diverse industry needs.

How Does Material Quality Affect Performance

Material choice affects both the mold and the end fittings. A Pipe Fitting Mold made from reinforced steel or high-grade aluminum withstands high temperatures and repeated use without warping.

For the fittings themselves, plastics like PVC, CPVC, or PPR offer strength, heat resistance, and durability. High-quality molds ensure consistent wall thickness, smooth surfaces, and precise dimensions, which are critical for leak-proof connections and long-lasting performance.

Are Custom Designs Valuable

Customization allows manufacturers to meet specific market requirements. A Pipe Fitting Mold can be designed to produce elbows, tees, reducers, or specialized connectors. Custom molds also enable unique branding features, such as embossed logos or identification markings, helping products stand out in competitive markets.

Suppliers providing flexible mold design options help manufacturers adapt quickly to new product specifications, project demands, or client requirements.

How Does Maintenance Influence Longevity

Regular maintenance is essential to extend the lifespan of a Pipe Fitting Mold. Cleaning, polishing, and inspection prevent defects like flashing, warping, or uneven surfaces.

Suppliers offering guidance on mold care and maintenance support long-term production stability. A well-maintained mold reduces downtime and ensures every pipe fitting meets quality standards.

Could Efficient Mold Design Reduce Costs

Optimized Pipe Fitting Mold designs improve plastic flow, reduce cycle times, and minimize waste. Proper gate placement, venting, and cooling channels allow smooth injection and uniform fittings.

This efficiency translates to lower production costs, faster turnaround, and higher output, which is especially important for bulk orders or wholesale distribution.

How Does Market Demand Influence Mold Selection

Demand for high-quality plumbing and industrial fittings drives mold selection. A versatile Pipe Fitting Mold allows manufacturers to produce standard and customized fittings to meet residential, commercial, and industrial needs.

Flexible molds enable quick adaptation to new standards, materials, or pipe sizes, keeping manufacturers competitive in evolving markets.

Are Safety and Compliance Considerations Essential

Pipe fittings often carry water, chemicals, or other fluids, making safety compliance critical. A Pipe Fitting Mold producing fittings that meet ISO, ASTM, or NSF standards ensures reliable performance and customer confidence.

Accurate molds prevent leaks, maintain structural integrity, and enhance durability, which is vital for plumbing systems, industrial piping, and irrigation networks.

Could Multi-Cavity Molds Increase Productivity

Multi-cavity Pipe Fitting Molds allow several fittings to be produced in a single cycle, improving production efficiency. This capability is particularly valuable for manufacturers handling large-scale orders, exports, or wholesale distribution.

High-efficiency molds reduce labor, optimize material usage, and maintain precise, uniform fittings, contributing to both cost savings and consistent quality.

What Should Buyers Verify Before Ordering

Buyers should confirm mold durability, material compatibility, precision, customization options, and after-sales support when selecting a Pipe Fitting Mold. Reviewing sample fittings, technical specifications, and warranty terms helps reduce production risks.

English

English русский

русский عربى

عربى 中文简体

中文简体